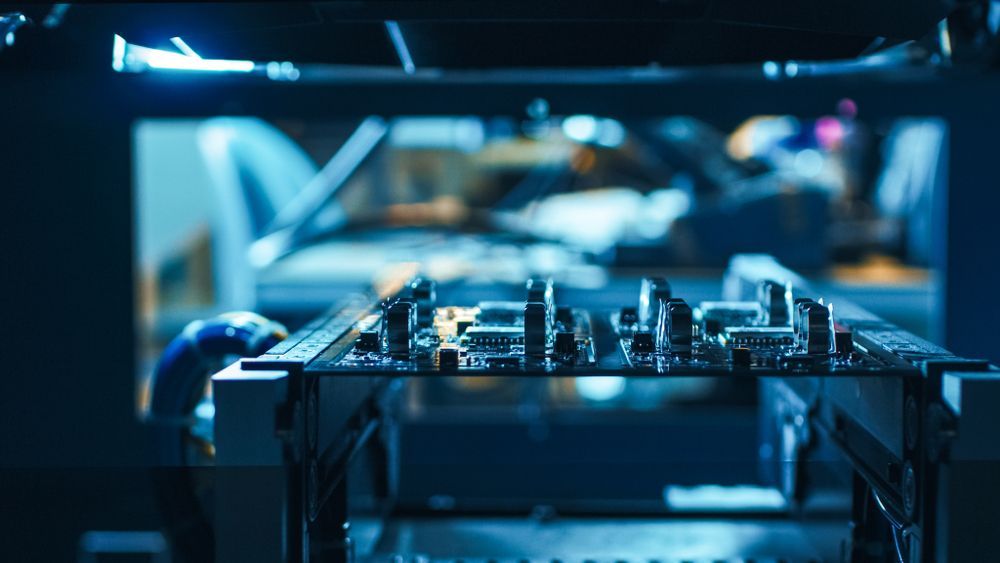

Printed Circuit Boards (PCBs) are the foundation of almost every electronic device we use today.

Whether it's a smartphone, computer, or household appliance, PCBs play a crucial role in connecting and powering various electronic components.

Selecting the right materials for your PCB design is essential to ensure its functionality, reliability, and overall performance.

In this article, we will explore the key considerations for choosing the right materials for your PCB design.

Importance of PCB Material Selection

The choice of materials greatly influences the PCB's characteristics, such as electrical performance, thermal management, mechanical strength, and cost.

Different applications require varying performance attributes, so it's crucial to understand the specific requirements of your design before making material decisions.

Common PCB Materials

FR-4: FR-4 (Flame Retardant 4) is the most widely used PCB material due to its excellent balance of performance and cost-effectiveness. It is a glass-reinforced epoxy laminate that provides good electrical insulation, mechanical strength, and dimensional stability. FR-4 works well for most standard applications.

High-Frequency Materials: For applications involving high-frequency signals, such as in telecommunications and wireless devices, special materials like PTFE (Polytetrafluoroethylene) or RF-4 can be used. These materials have lower signal loss and better impedance control, crucial for maintaining signal integrity at high frequencies.

Metal Core Materials: When dealing with high-power applications or devices requiring efficient heat dissipation, metal core materials like aluminium-backed or copper-backed laminates are preferred. These materials help conduct and dissipate heat away from heat-generating components.

Flexible Materials: For applications where the PCB needs to be flexible or have a specific form factor, flexible materials like Polyimide (PI) or Polyester (PET) are suitable. They are commonly used in wearable devices, medical products, and aerospace applications.

Key Considerations for Material Selection

Operating Environment: Consider the operating conditions of your PCB, including temperature range, humidity, and exposure to chemicals or outdoor elements. The chosen materials should be able to withstand these conditions without degrading their performance.

Signal Integrity: If your design involves high-speed signals or RF circuits, the dielectric constant and loss tangent of the PCB material becomes crucial. Lower dielectric constant and loss tangent result in better signal transmission and reduced signal distortion.

Thermal Management: For power-intensive applications or components that generate heat, selecting materials with high thermal conductivity is essential. Efficient thermal management ensures the components operate within their temperature limits and enhances the overall reliability of the PCB.

Mechanical Strength: Consider the mechanical stress and strain the PCB may experience during its lifetime. The material should have sufficient mechanical strength to withstand these forces without developing cracks or failures.

Cost: While it's essential to choose the right materials for your PCB design, cost considerations cannot be ignored. Balance the performance requirements with the available budget to optimise the material selection.

Manufacturability: Ensure that the selected materials are compatible with your PCB manufacturer's processes and equipment. Some materials may require specialised handling or manufacturing techniques.

RoHS Compliance: The chosen materials should be compliant with environmental regulations such as the Restriction of Hazardous Substances (RoHS) directive.

Consulting with PCB Manufacturers. It is highly recommended to involve your PCB manufacturer early in the material selection process. They have valuable expertise and can guide you in choosing materials that align with your design requirements and are suitable for their manufacturing processes.

Conclusion

Selecting the right materials for your PCB design is a critical step in ensuring its functionality, reliability, and performance.

Collaborating with experienced PCB manufacturers will help you navigate the complexities of material selection and lead to a successful and efficient PCB design.

Remember, investing time and effort in choosing the appropriate materials will pay off in the long run, resulting in a high-quality and reliable electronic product.

Call

01189 455377 or follow us on

Twitter to learn more about our products and services.