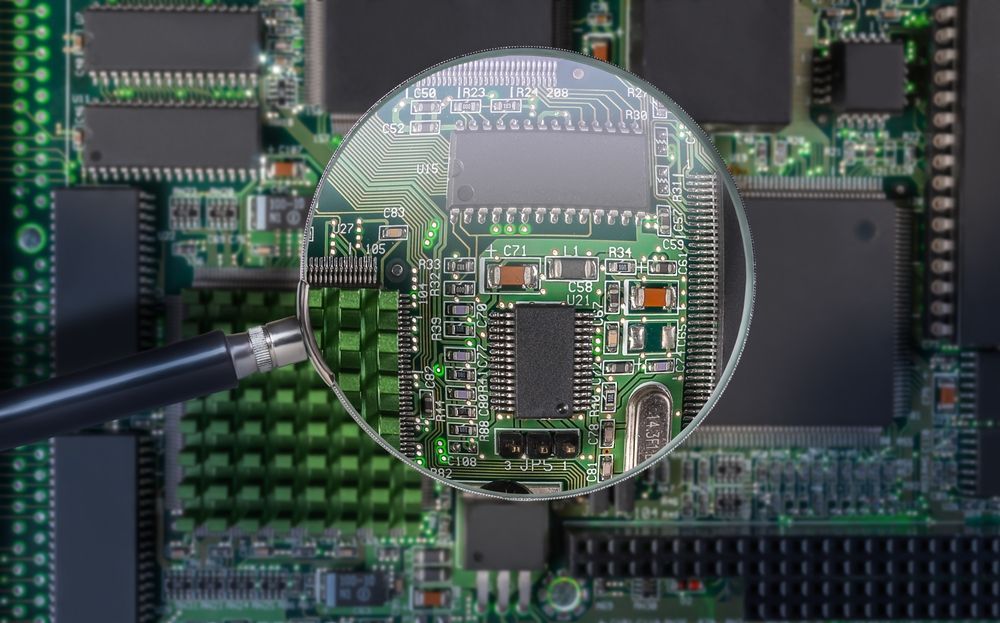

Surface Mount Technology (SMT) assembly has revolutionised the electronics manufacturing industry by enabling smaller, lighter, and more efficient electronic devices.

As the demand for consumer electronics and IoT devices continues to rise, manufacturers must also address environmental concerns associated with the manufacturing process.

Implementing eco-friendly practices in SMT assembly not only promotes sustainable manufacturing but also aligns businesses with global environmental regulations and customer preferences.

In this article, we will explore five critical environmental considerations in SMT assembly and how they contribute to greener and more responsible electronics manufacturing.

Lead-Free Soldering

One of the most significant environmental advancements in SMT assembly has been the shift towards lead-free soldering. Traditional soldering processes often involved lead-based solder, which posed environmental and health risks.

However, with the introduction of RoHS (Restriction of Hazardous Substances) regulations, lead-free solder has become the norm. Lead-free solder offers comparable mechanical and electrical properties while reducing the environmental impact associated with lead contamination.

Waste Minimisation

SMT assembly generates various types of waste, including excess solder paste, defective components, and trimming scraps.

Embracing waste minimisation strategies is crucial for reducing the environmental footprint of manufacturing processes.

Implementing precision solder paste dispensing, accurate component placement, and employing automated optical inspection (AOI) systems for quality control can significantly reduce material waste.

Additionally, recycling programs for discarded components and proper disposal of hazardous materials are essential for responsible waste management.

Energy Efficiency

SMT assembly processes can be energy-intensive, particularly during reflow soldering and component testing phases. Manufacturers can adopt energy-efficient practices to lower their carbon footprint.

Employing advanced reflow ovens with precise temperature control can optimise energy consumption during soldering.

Furthermore, automating certain steps in the assembly line reduces energy consumption by streamlining processes and minimising idle time.

Sustainable Material Selection

Careful consideration of materials used in SMT assembly plays a vital role in reducing environmental impact. Opting for eco-friendly and recyclable packaging materials for components can minimise waste generation.

Additionally, selecting components with extended lifespans and higher reliability can help prolong the life of electronic devices, reducing the need for frequent replacements and, in turn, lowering electronic waste.

Emission Control

Air quality and emissions are significant concerns in manufacturing facilities. SMT assembly processes may release volatile organic compounds (VOCs) and other harmful substances into the atmosphere, contributing to air pollution.

Employing efficient ventilation systems and investing in air filtration technologies can help control and reduce emissions. Regular maintenance of equipment and machinery also ensures optimal performance and minimises the release of harmful substances into the environment.

SMT Assembly: Conclusion

In conclusion, environmental considerations in SMT assembly have become a top priority for electronics manufacturers aiming to operate responsibly and sustainably.

From adopting lead-free soldering to minimising waste and energy consumption, every step towards greener manufacturing practices contributes to a healthier planet.

By implementing eco-friendly measures and technologies, electronics manufacturers can not only comply with environmental regulations but also appeal to environmentally conscious consumers who seek products with a reduced carbon footprint.

Embracing these environmental considerations not only benefits the planet but also fosters a positive reputation for businesses in an increasingly environmentally conscious world.

Call

01189 455377 or follow us on

Twitter to learn more about our products and services.