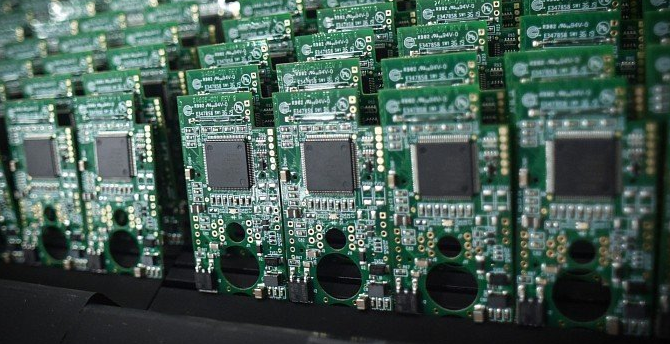

PCB Assembly & Design

In the manufacturing industry, there are many types of assembly methods to produce a final product. One type is printed circuit board assembly (PCB). PCBs can be found in almost every electronic product and component that we use today. The process consists of placing components on a substrate like fibreglass or epoxy resin and then creating electrical connections between them by soldering. This creates the path for electricity to flow through the board allowing it to power different devices such as computers, microwaves, phones, etc… When these boards fail it can cost manufacturers thousands of dollars due to reworking costs and customer complaints about malfunctioning products. Here at M-Tek Assembly., we specialise in PCB assembly services including: surface mount technology (SMT), thru-hole technology

Manufacturers and manufacturers of electronics products have a lot to consider when designing their product. One of the most important considerations is how they will assemble components into a functioning unit that performs as expected. Printed circuit board assembly (PCB) is one method that can be used for this process, and it requires careful planning before implementation.

Professional tone with information about PCB assembly.

Which are the various ways to create printed circuit board assemblies?

The printed circuit board assembly is an essential part of the electronics industry. The PCBs are used to house and connect electronic components together in a functional unit. Creating

PCB assemblies can be done through various ways including pick-and-place, reflow soldering, wave soldering, etc. This blog post will focus on these methods and their advantages and disadvantages to give you a better understanding of how they work. We'll also discuss other important elements that go into creating printed circuit boards such as design rules for reference layers (RDL) and design rule checks (DRC).

The Surface Mount Assembly (SMT)

The Surface Mount Assembly (SMT) industry has been around for decades and is still thriving today. SMT technology is the process of assembling electronic components onto a PCB board, which comes in various sizes and shapes depending on your product or project. There are many different types of surface mount equipment used to complete the assembly process: pick-and-place machines, ovens, reflow systems and more. All these pieces work together to create a fully functional circuit board that will be able to play its intended role within your product or device.

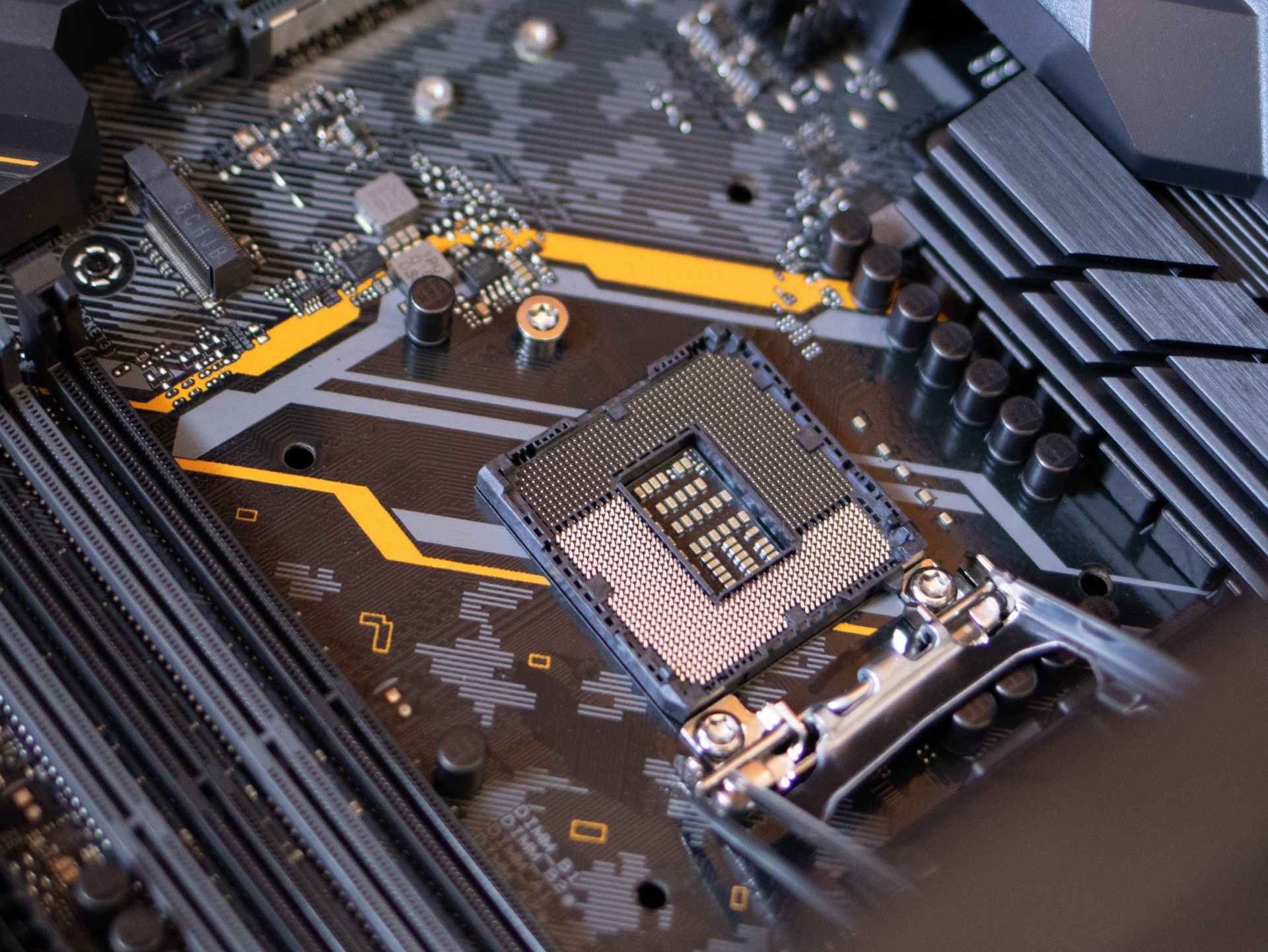

Plated through-hole technology (PTH)

Plated through-hole (PTH) technology is a method for the manufacturing of electronics. It involves using copper, which is plated on both sides of the board with solder before it's soldered down to another surface. This process makes PTH parts more reliable than other kinds of connections because they are able to handle higher power densities and heat fluxes. The plating not only protects against corrosion, but also provides additional strength to the connection between components that have been soldered together. Overall, this type of technology allows for electronics manufacturers to produce cheaper products with better performance capabilities.

Electro-mechanical assembly

Electro-mechanical assembly is a sub-assembly process of the manufacturing industry. It typically involves soldering, bonding, riveting or welding parts together to create an assembled product. The most common materials for this type of work are copper, aluminum and steel.

The process can be carried out in a variety of ways depending on the needs of the customer and their budget constraints. Some manufacturers offer "turnkey" services which involve managing all aspects from design through to assembly with no need for outside assistance while others only provide part components that need to be put together by another company's staff. Electro-mechanical assembly is often used as more cost effective means of production when compared to other methods such as stamping or forging

Which are the various ways to create printed circuit board assemblies?

PCB assembly is a process for attaching electronic components to the circuit board. With so many options on where and how to get your boards assembled, it can be tempting just to go with what’s easiest or cheapest without considering that those decisions might cost you more in the long run. That doesn't have to happen if you're willing to invest some time up front into finding an expert who will work closely with you throughout each step of the design and production processes. To learn more about our full-service PCB assembly services, please

contact us today!

About M-TEK ( Assembly ) Ltd:

M-TEK (Assembly) Ltd is a contract electronics manufacturing company (CEM) based in the South East of England in Berkshire, UK. For over 19 years, M-TEK has been providing its customers with quality electronics services by constantly assessing customer needs and requirements. From products Design for Manufacture (DfM) through to PCB assembly, cable harness manufacture and full box build, M-TEK has organically developed through investment in plant and personnel, offering a complete solution for electronics prototyping and assembly focusing on IoT Products.