What are Surface Mount Devices?

As the world of technology continues to advance - so too does the need for more efficient and effective methods of completing tasks. Surface mount devices (SMDs) are a type of electronic component that has become increasingly popular in recent years due to their ability to save time, money, and space. In this article, we will explore what SMDs are, their advantages, and how they can help businesses.

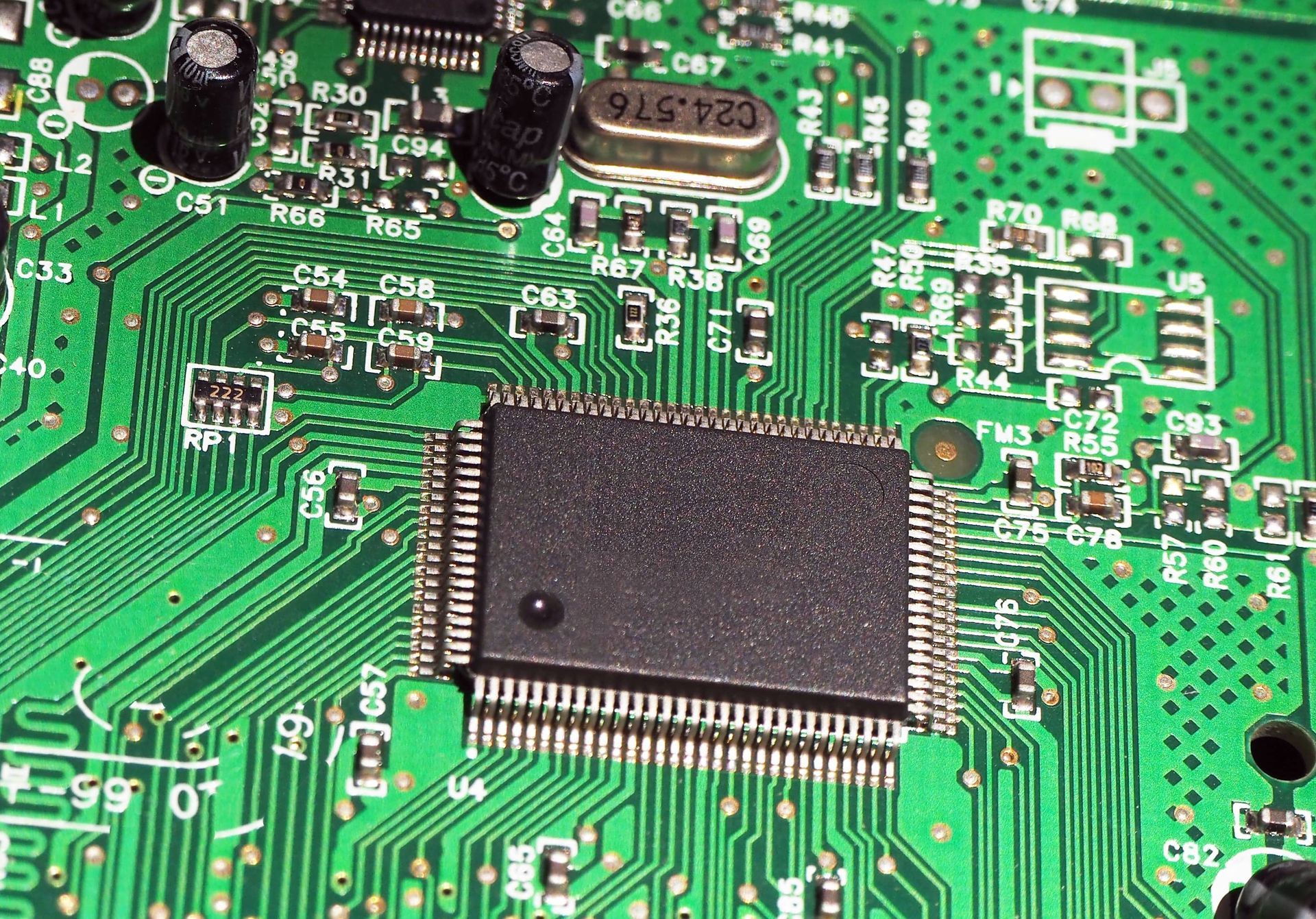

What are Surface Mount Devices?

Surface mount devices are small components that are typically used in electronic circuits. These components are typically much smaller than their through-hole counterparts, and they can be placed directly onto the surface of a circuit board characterised by their low profile, small size, and weight - which makes them ideal for use in a variety.

SMDs are available in a variety of shapes and sizes, and they can be tailored to meet the needs of any specific application. They can be used in a variety of applications, including automotive, consumer, industrial, medical, and telecommunications.

Benefits of SMDs

SMDs have various advantages over through-hole components. For one thing, they can be placed directly on the surface of a circuit board, without the need for additional mounting gear. This also minimises the amount of installation area required, which can result in considerable cost savings. Furthermore, SMDs require fewer steps and are much faster to assemble, which can contribute to higher yields and shorter assembly times.

Another advantage of SMDs is that they can resist higher temperatures. As a result, they are suited for applications requiring enhanced thermal dissipation, such as consumer electronics and automotive. Furthermore, because of their reduced size and larger contact area, SMDs are frequently more dependable than through-hole components.

Applications of Surface Mount Devices

SMDs have several uses, including consumer electronics, automotive, industrial, medical, and telecommunications. They are frequently employed in consumer electronics to minimise the size and weight of components, which can result in cost savings. They are frequently used in automobiles to reduce component size and weight while also increasing thermal dissipation. SMDs are frequently employed in high-temperature conditions in industrial applications, such as semiconductor production.

Due to their compact size and greater dependability, they are frequently used in implanted devices in medical applications. Finally, SMDs are frequently employed in telecommunications due to their capacity to minimise the size of circuit boards while increasing the number of components that may be placed on the board.

Conclusion

Surface mount devices are a type of electronic component that has grown in popularity in recent years because of their ability to save time, money, and space. SMDs come in a range of forms and sizes, and they may be customised to match the requirements of any specific application. Nevertheless, SMDs have various advantages over through-hole counterparts, including higher temperature resistance, lower size, and increased contact area. SMDs have several uses, including consumer electronics, automotive, industrial, medical, and telecommunications.

If you’re looking for ways to save time and money on your next project, consider using surface mount devices. With their small size, increased reliability, and ability to withstand higher temperatures, SMDs can help you achieve your goals faster and more cost-effectively.

By choosing M-Tek for your surface mount device assembly, you will also be doing your part to save the planet. We have achieved a net-zero carbon footprint from our use of electric vehicles, and for every circuit board we build, we plant a tree! Get in touch with one of our experts for help with your SMD and PCB assembly today. Call us on 01189 455377, or follow us on

Twitter to stay up to date with our services.