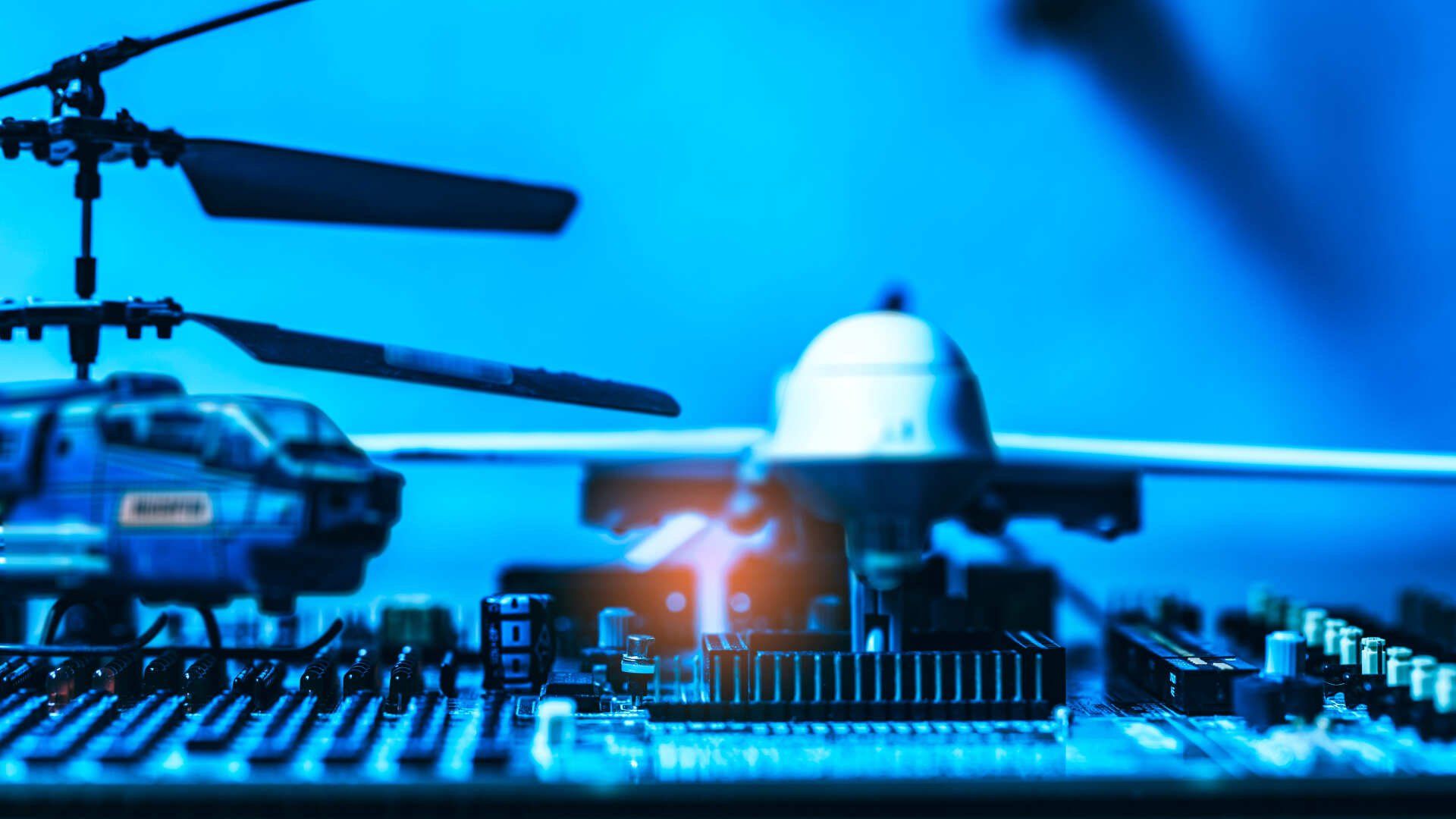

Military Designed PCBs

When it comes to applications, the military is one of the most demanding sectors. The systems or devices used in these industries must be of the highest quality. Military Grade PCBs must be highly reliable and have long service lives in harsh environments. In these demanding environments, high-temperature laminates, copper and aluminium substrates can perform admirably. Heat-induced oxidation can be eliminated by using anodized aluminium. Aluminium substrates combined with thermally conductive pre-pregs provide military designers with performance and weight benefits.

Because of their importance in electronics, printed circuit boards have a wide range of applications. The military sector is one of the most important application areas. However, due to the nature and sensitivity of this unique sector, you may know very little about military-grade PCB. So, what exactly is it all about?

Military PCB Manufacturing

Military-grade elements necessitate a high level of quality control and strict tolerance levels, which may be impossible to achieve with traditional manufacturing methods. Military PCB manufacturing has developed to produce components and boards for high-stress applications.

Printed circuit boards are required for military applications. The harsh environment that characterises the military, on the other hand, necessitates a highly reliable PCB. It is unheard of for a printed circuit board to function normally in an environment with continual interaction and engagement with contaminants, extreme temperatures, and chemicals. This is where the military-printed circuit board enters the picture.

Military PCBs must meet or exceed the requirements and guidelines established by the relevant military. As a result, depending on the requirements and specific application area specified by the military, such printed circuit boards are of various types. As a result, the board specifications will be determined by the type of military PCB. Furthermore, specific design features must be considered from theorising to manufacturing.

Military Printed Circuit Board Design

The theorising and design of the PCB are frequently the first steps in the entire circuit board production process, and as such, are not dissimilar to a military PCB. It includes a variety of factors to consider, including the type of military PCB. So, what are these factors?

Materials for the board are an important part of a military PCB design because you must ensure that every material meets military-grade standards and specifications. Because military PCBs are used in harsh weather conditions, the materials used to develop them must be heat resistant. Furthermore, the use of thermal compounds becomes critical in assisting with heat dissipation. In this case, the printed circuit board stack-up denotes the layer number required for a military PCB. This must be determined during the design phase to helping you understand the required impedance for each layer, as well as the best fabrication process to use. Such determinations aid in determining the expected yield, lowering production costs, and ensuring reliability.

Copper traces on a printed circuit board circuit are critical for transmitting electrical and other types of signals in the PCB. During the design phase, it is critical to understand the properties of copper traces in addition to their limitations. The type of via is also important in connecting the various military components on the military PCB. Through-hole, blind, micro, and buried vias are all included. All high-quality PCBs, on the other hand, have fewer vias. Furthermore, when designing the PCB, the current carrying capacity of the via becomes an important factor to consider.

A military PCB contains many military components rather than just one. As a result, you will need to account for this in your design, which will necessitate a variety of military component types. To reduce errors and ensure high PCB quality, it is critical to select the correct components for your military PCB. Following the considerations already outlined, it is necessary to consider the design rules. Component placement, DFM, layer allocation, cross-talk budgets, and flight time should all be considered. Other components that will interact with the PCB, such as military-grade capacitors, must be considered in the military PCB design.

A high-quality military printed circuit board has strong audio and signal integrity. Key considerations for this aspect should include a signal rise and fall times, characteristic impedance, rack lengths, and drive strength. However, for a quality performance guarantee, the signal integrity simulation must begin both before and after the layout. Furthermore, the DC and AC performance of the power distribution must be considered.

About M-Tek Assembly Ltd

Here at M-Tek Assembly, we have years of industry experience, and our team of skilled engineers will guide you through the entire process. You will also be helping to save the environment by using M-Tek for PCB repairs. We have achieved a net-zero carbon footprint by using electric vehicles, and for every circuit board we build, we plant a tree! Contact one of our SMT and PCB assembly experts today for assistance. Call 01189 455377 or follow us on Twitter to learn more about our services.