Our Objectives and Services

Our Contract Electronic Manufacturing Company

NPI & Product Support

Here at M-TEK, our PCB assembly experts have always believed in "the customer always comes first”.

Founded in 1996, we pride ourselves on our long-standing relationships with both our customers and partners in a variety of industries. All to ensure our investment is with the people and developing technological advancements, through product support in the contract electronic manufacturing industry.

Our objective is to offer this commitment to existing and new customers alike. We want to continue to expand our printed circuit boards services, into new sectors and industries.

Capabilities & Services

- Sub-Micron X-RAY Inspection

(Digital & Oblique Views)

- SMT & PTH Assembly

(Small, Medium & Volume Production)

- PCB Assemblies

- Flexi-Rigid and Flexi Circuits Assemblies

- Package on Package (PoP) Assemblies

- μBGA/BGA Reballing and repairs

- Rapid Prototyping (NPI to Volume)

- Testing & Programming

(Flying Probe, ICT, X-JTAG, ESS)

- Debugging & Product Support

- Complete Box Build

(inclusive of Cable Assemblies)

- UK & Global Procurement Services based on a Audited Secured Supply Chain

- Vacuum Casting & 3D Prototyping

Our portfolio of services and partners currently encompasses the following industries:

Services

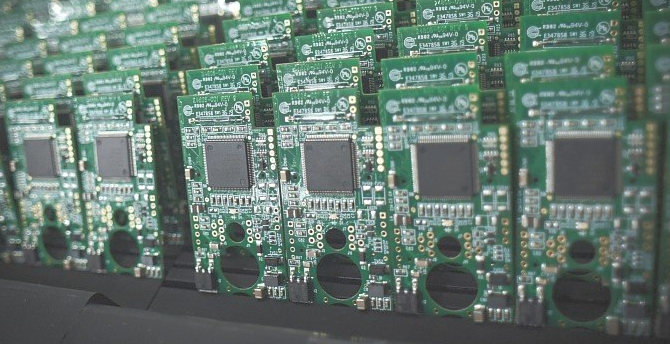

At M-TEK, we offer a wide range of contract electronic manufacturing services, including MRP software, vacuum casting and printed circuit boards.

Our comprehensive equipment life, along with our experienced and qualified team, is able to offer our customers a more responsive, efficient and tailored approach to prototyping and PCB assembly requirements.

- NPI, Rapid Prototyping, Product Testing & Integration & Complete Box Builds

- Mixed Technology Double Sided PCB assemblies (SMT& Conventional)

- Sub-micron Digital X-RAY Inspection with 70 ° Oblique Viewing Capability

- AOI with Laser Coplanarity Capability Module for QFN, LGAs, BGAs and ICs

- Design for Manufacture & Specialist Repairs Scenario Capability

- Turnkey Product Assembly & Test (Full Procurement)

- Electromechanical Assembly

- Vacuum Casting & 3D Prototyping

Quality Management System - Our Aim is Zero Defect!

Here at M-TEK, we understand the importance of quality and reliability. That is why we aim to provide complete customer satisfaction and that programmes are delivered on time, efficiently and without defects. Our PCB assembly experts check the quality of every product and ensure that the printed circuit boards meet the highest standard in the contract electronic manufacturing industry before shipping.

Our M-TEK team are committed to delivering high-end services at a cost-effective price. All to meet your specific assembled PCB requirements, on time and within budget. All our services are controlled in accordance with the commitments of our QMS and our sites and partners are ISO 9001.

Get your PCB assembly quote here to see how we can help you today.

Our Quality PCB Assembly Services Include:

- High accuracy 3D measurement system

- X-ray - investigating for die placement accuracy, BGA shorts, faulty components, counterfeit components and trace and wire bonding contacts/connection

- Complete capability of environmental testing through our Partners

- Mechanical Tests and Control Certified IPC trainers ( IPC-A-610, WHMA-620, J-STD-001)

- Design for Manufacture & Specialist Repairs Scenario Capability

- Instruments for measurement of precision, temperature, force, electricity, tension, ESD, cleanliness

- Execution of Customised Quality Plan for Each Project

- Extensive use of quality tools (Histograms, Ishikawa diagrams, Kaizen Methodologies, etc)

- Equipment and Process Qualification

- Manufacturing Process Validation

- Design for Manufacture Reviews for all New Product Introduction